What is Plasma?

The process of the “Molecular Dissociator” with Plasma System is a drastic thermal process (up to 7000 degrees) of not incineration, but “sublimation”. Plasma is the fourth state of the matter, discovered by British physicist William Crookes in 1879 . Firstly used by the metallurgical industry in the 1800s for metallurgical and mechanical operations and in 1900 by the chemical industry to produce acetylene from natural gas. Plasma technology was used by NASA in the 1960s and has since become popular.

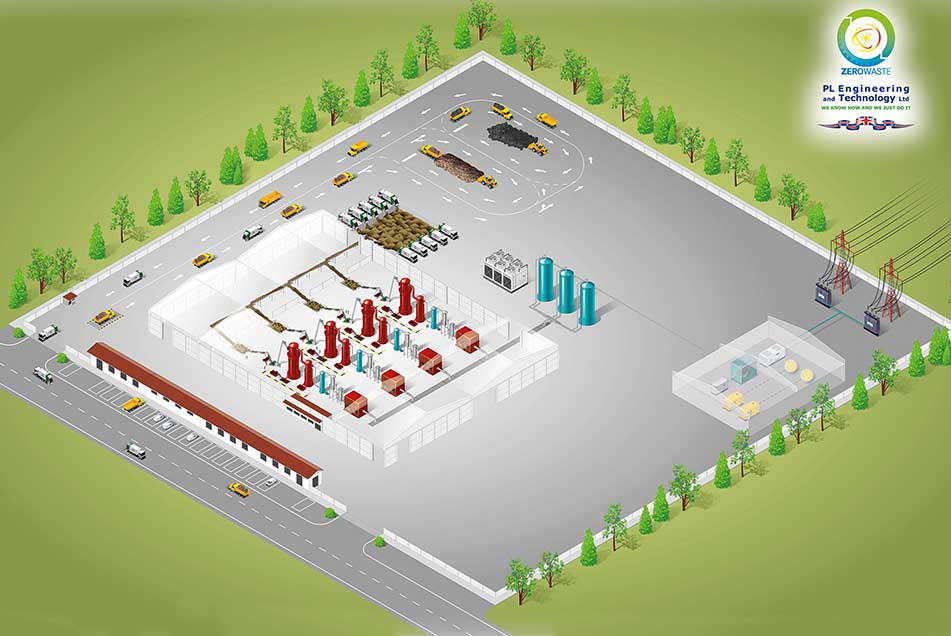

Molecular Waste Dissociation Plant with Plasma Technology

PL Engineering and Technology Ltd, presents the technology of Plasma Molecular Dissociation, used for the construction of alternative plants for waste disposal and energy production, a waste management system with clean technology.

The technology for the Molecular Dissociation of matter derives from aerospace research activities developed in the USA by NASA (as well as in France and the former USSR), in particular for the testing of materials to protect spacecraft from friction and heat developed during re-entry into the atmosphere.

The basic principle of this technology is focused on the Molecular Dissociation (decomposition into the elementary atoms of which the molecules are made) of the organic components of the waste (and on the fusion of the inorganic components) operated at very high temperature inside a closed reactor (Plasma converter),without combustion and therefore without emission of fumes and without production of ash (there are no chimneys as the final products of the reactions, after appropriate cleaning treatments of the synthesis gas, are sent for specific uses or, possibly, introduced into the distribution network).

Indicators of environmental sustainability of the Plasma Molecular Dissociation process

The Plasma Dissociation is the most innovative and “clean” waste disposal technology from an environmental point of view. The `Plas` is composed exclusively of hydrogen and oxygen, both of these components play an active role in redox reactions. In addition, the action of the plasma jet at extremely high temperature (in most cases above 5000 ° С), within a large space, is able to decompose any matter of organic and biological nature, ensure a complete destruction of the most powerful toxic substances, melt and vaporize inorganic substances characterized by the high degree of refractoriness.

The transformation process will yield two types of product

Vitrified SLAG

Vitrified SLAG or, in any case, low in content carbon, are completely inert residues and accumulate at the bottom of the furnace helping to maintain the high temperature inside the Plasma Reactor chamber. If the slag is cooled by air, it forms black, glassy rocks that look like obsidian; they can be used in concrete or asphalt or can be turned into bricks or stone molds for paving, and then air-cooled into ready-to-use building material.

SYNGAS

Syngas is a mixture of several gases, but it mainly includes hydrogen and carbon monoxide. It can be used as a fuel source and some plants use it both to supply power to the plant and to sell excess electricity to the power grid. Waste contains a large amount of potential energy; the Plasma Molecular Dissociation process allows engineers to convert potential energy into electrical energy. If the waste contains a lot of carbon-based material (in other words, organic waste), you will get more gas. Waste with a lot of inorganic material will not produce as much gas. For this reason, some plasma facilities sort waste before entering the system.